Take a tour of our state of the art engine machining and building facility

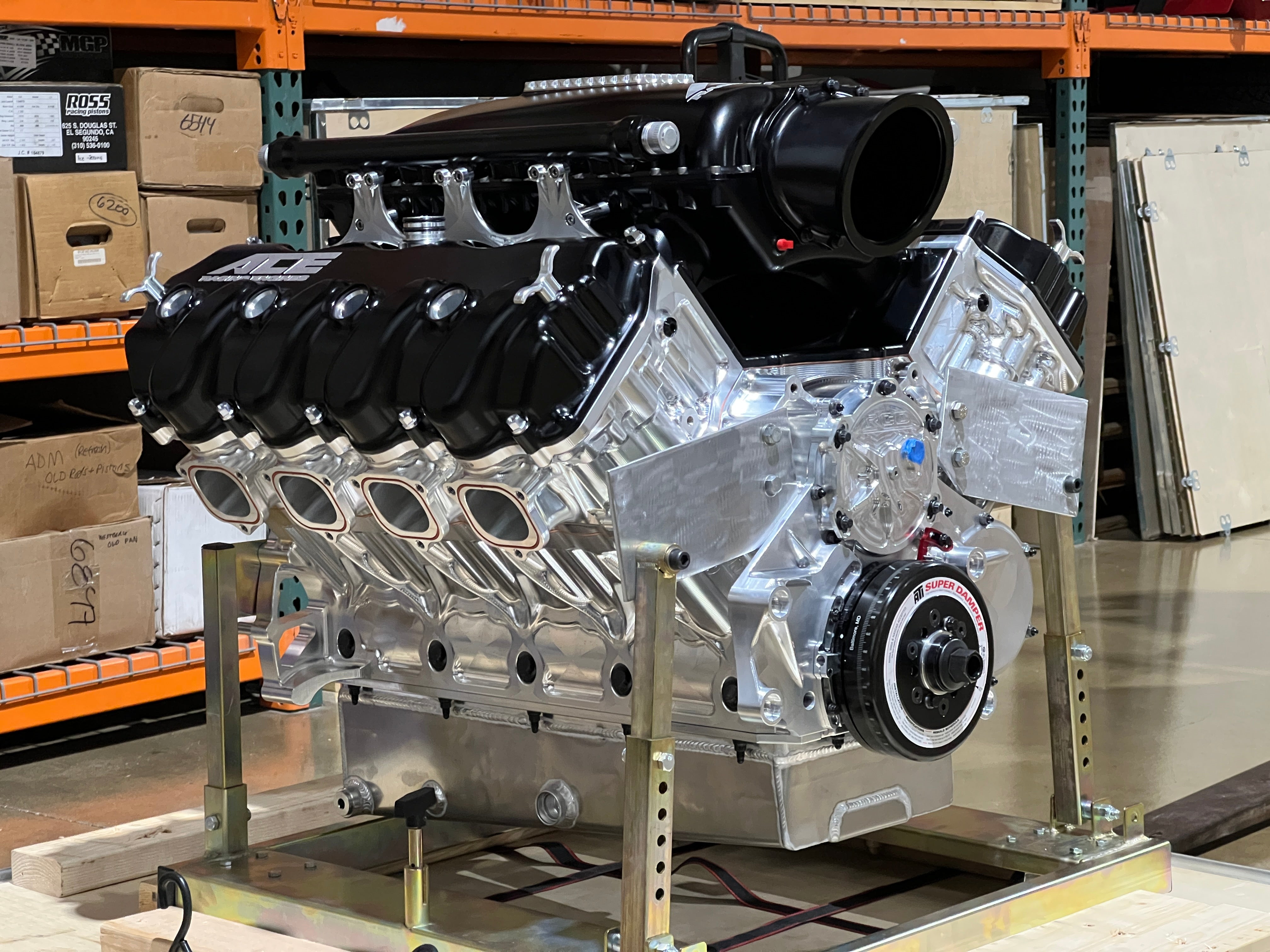

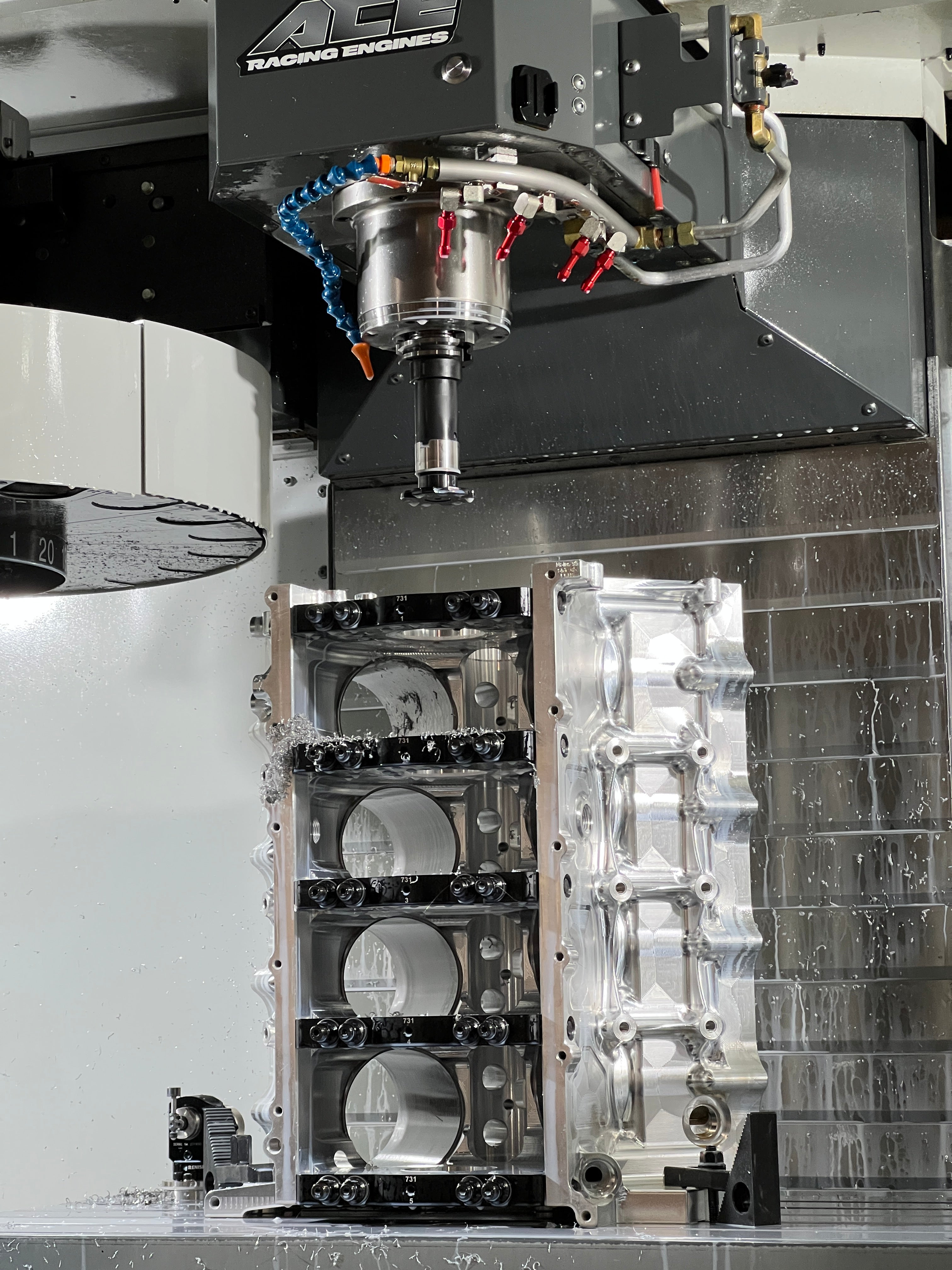

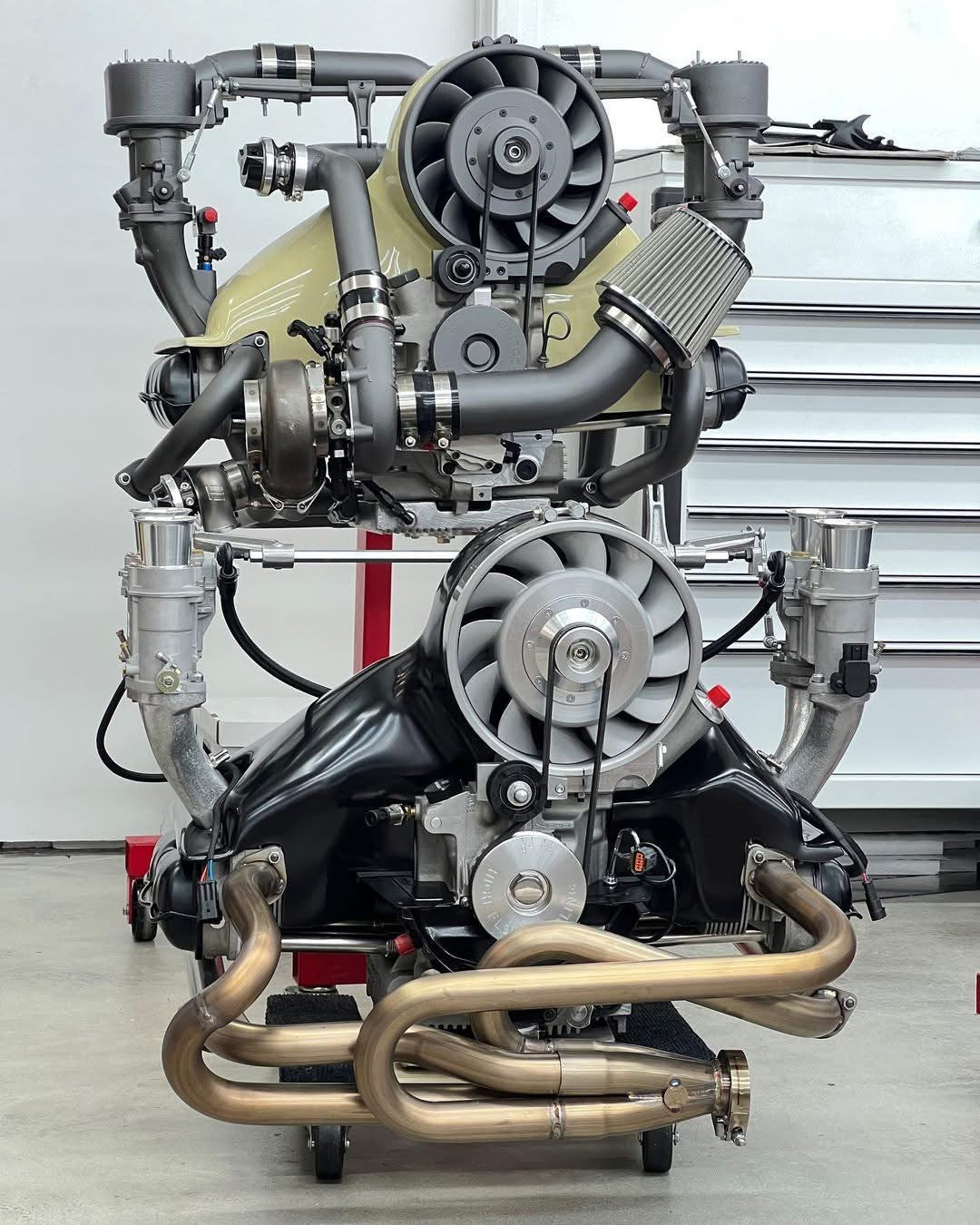

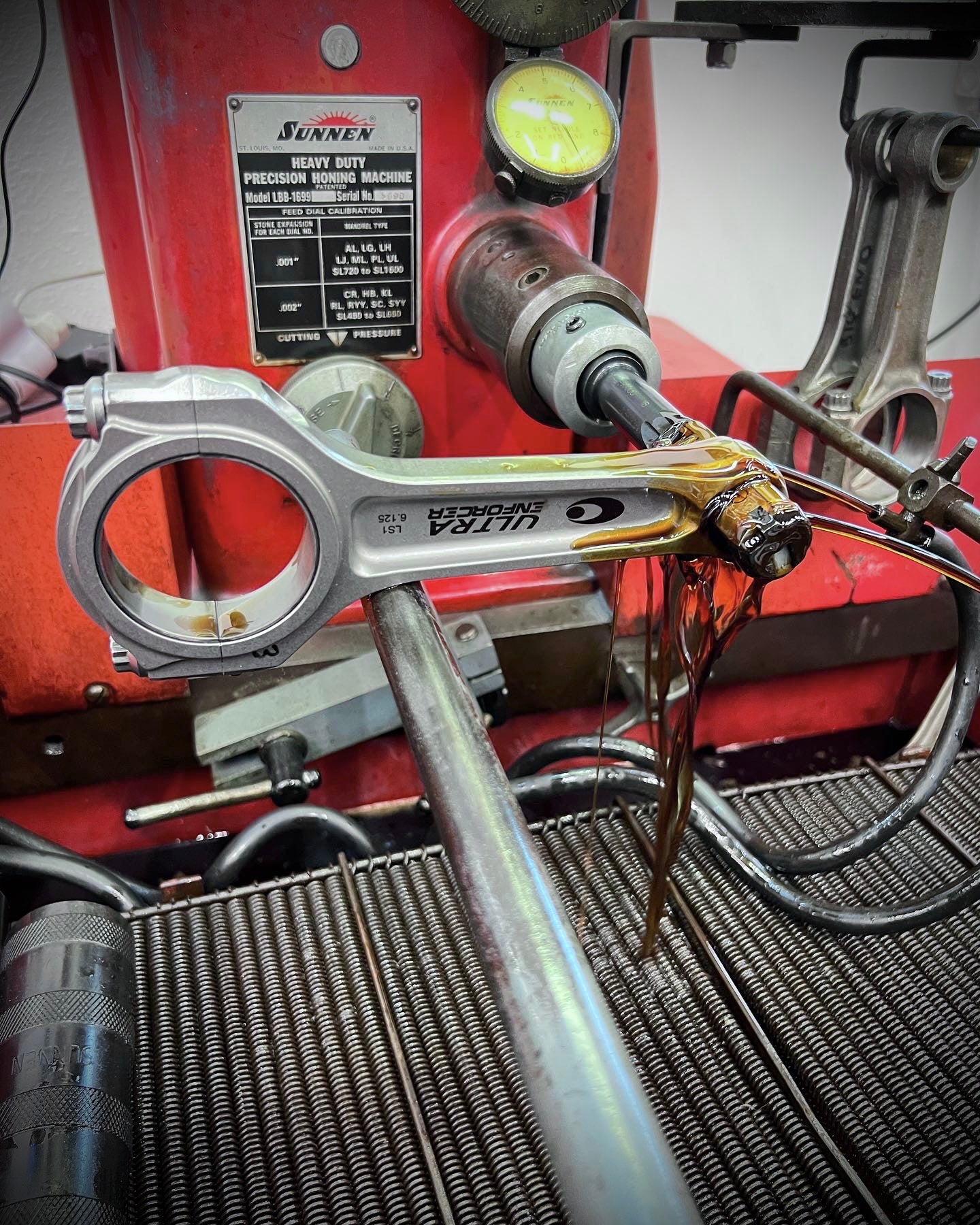

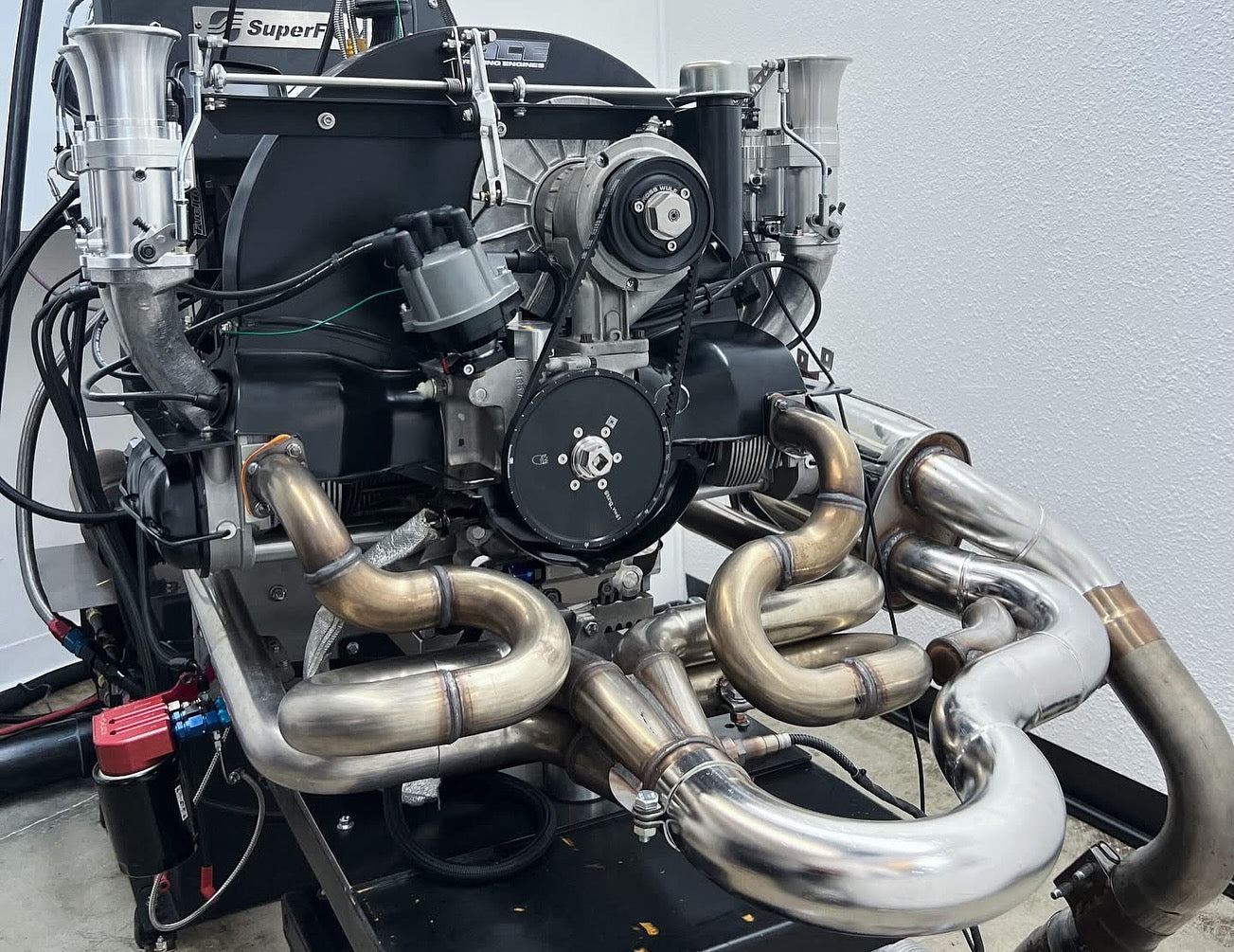

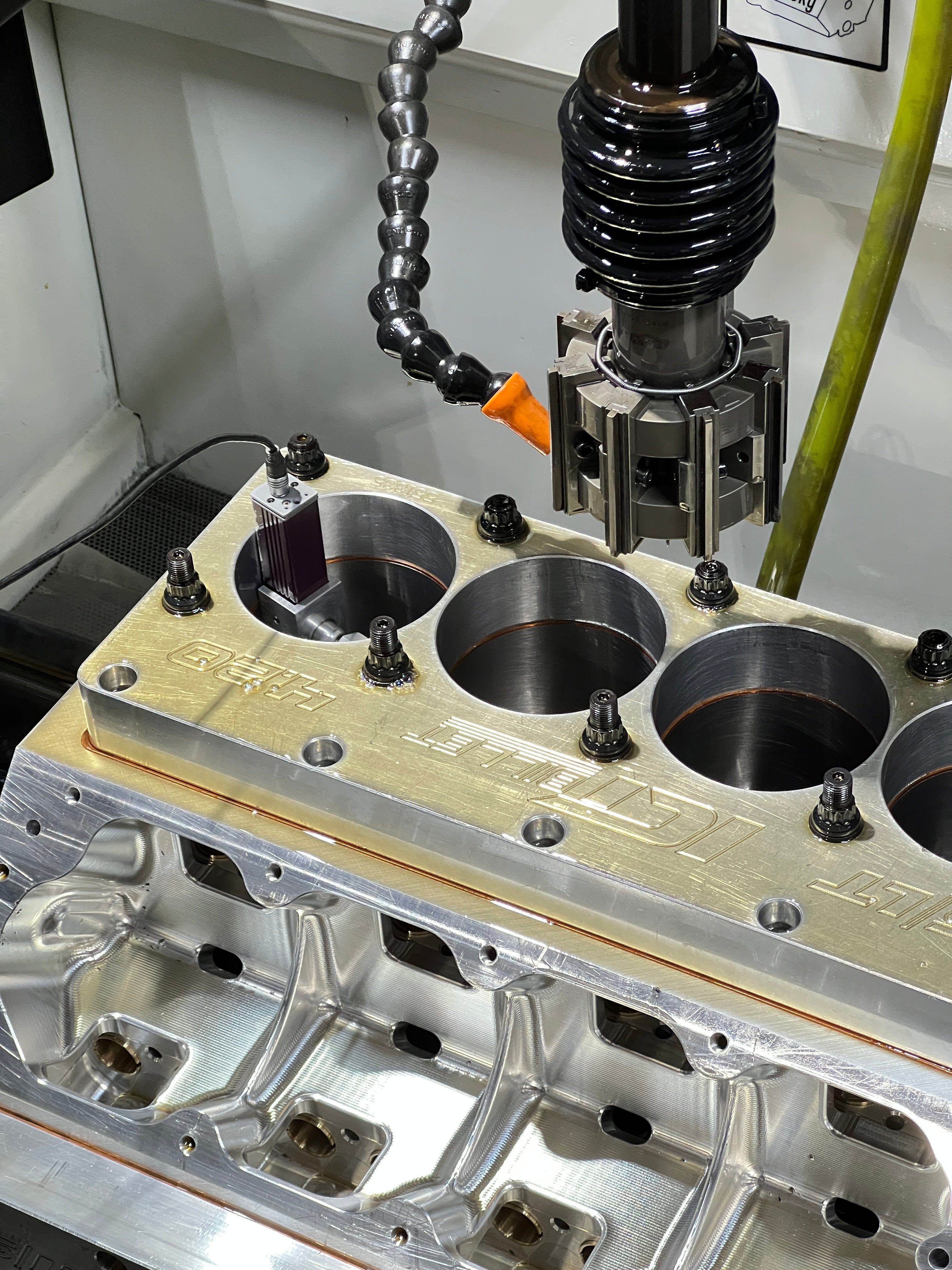

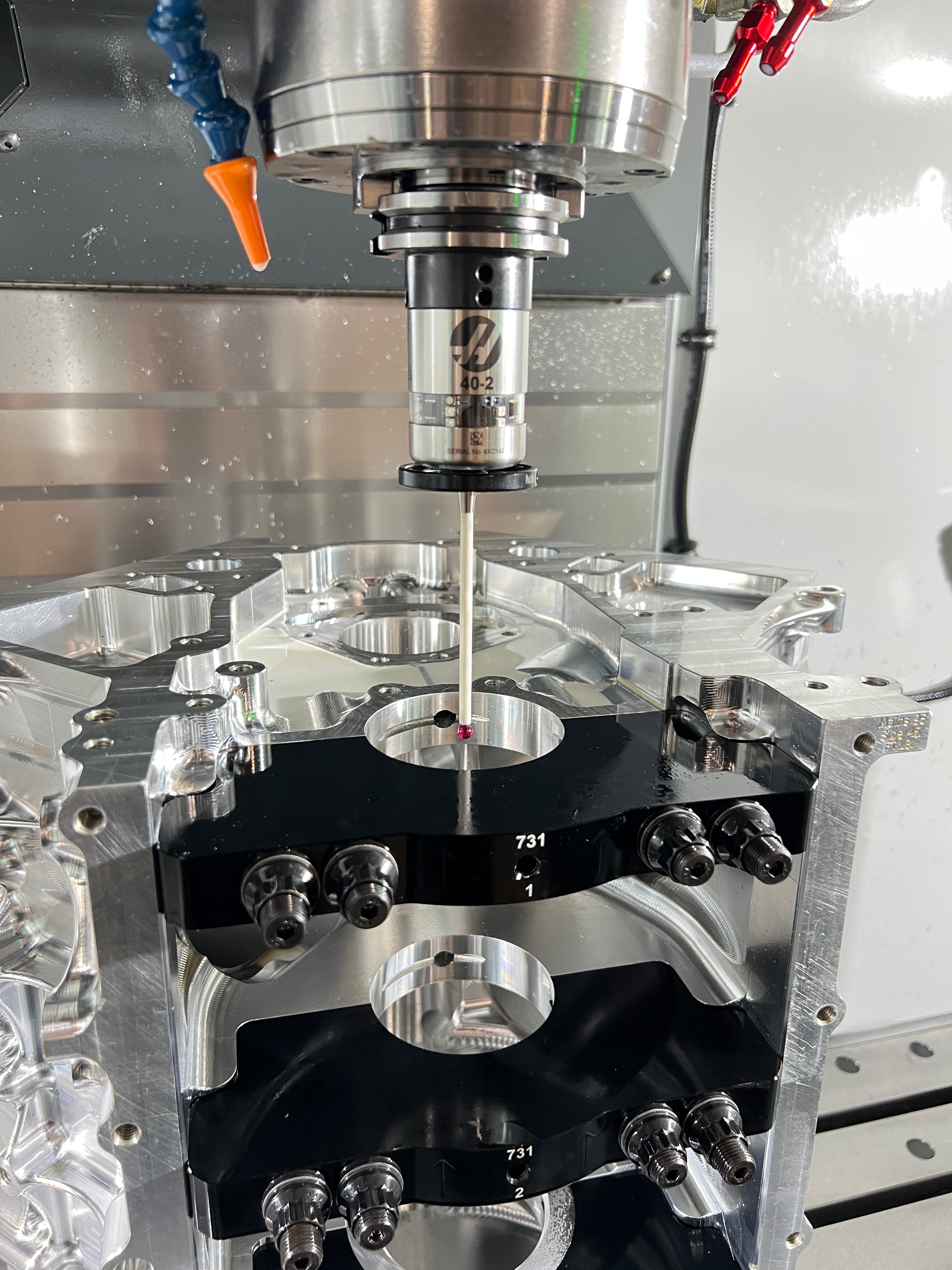

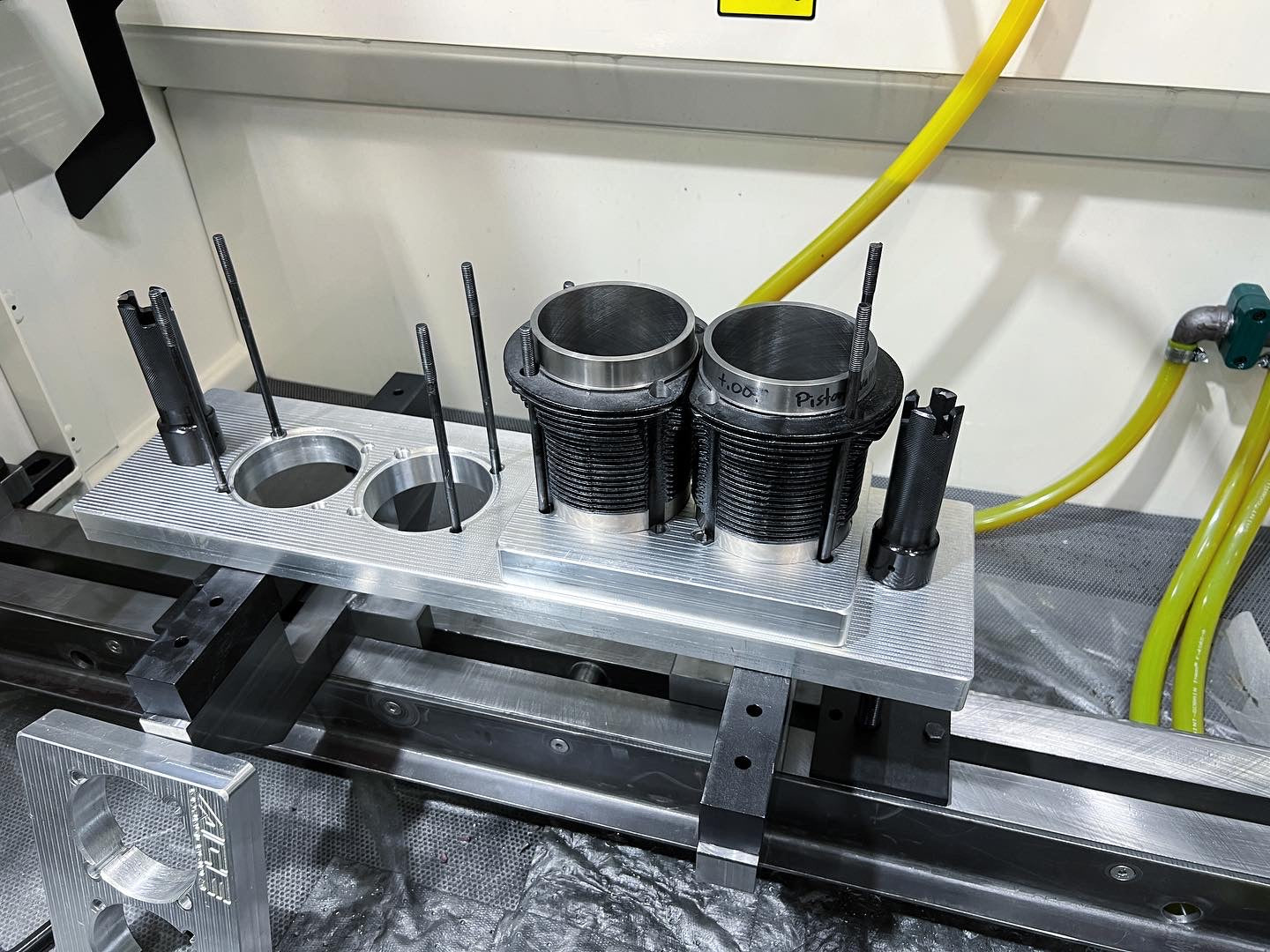

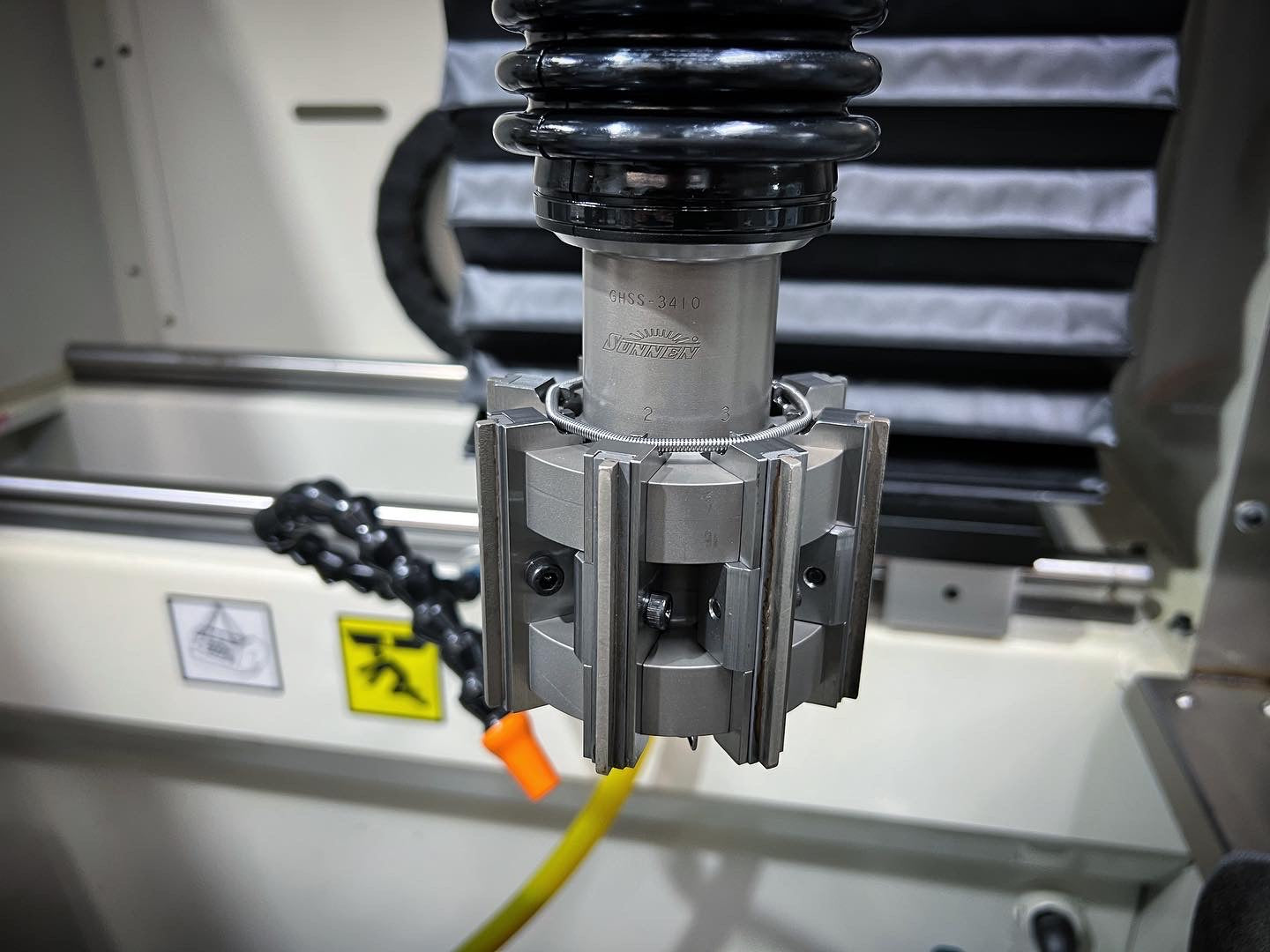

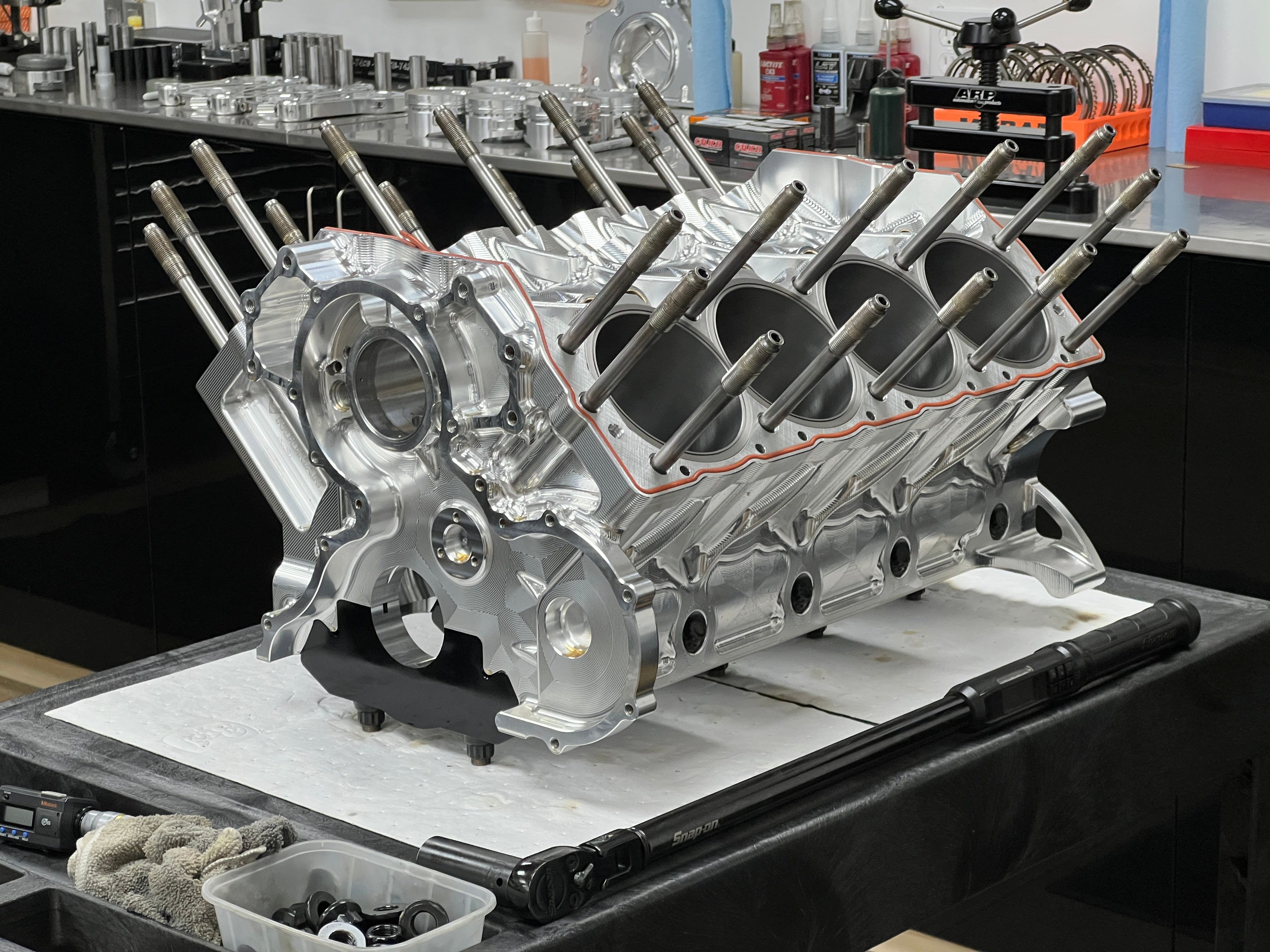

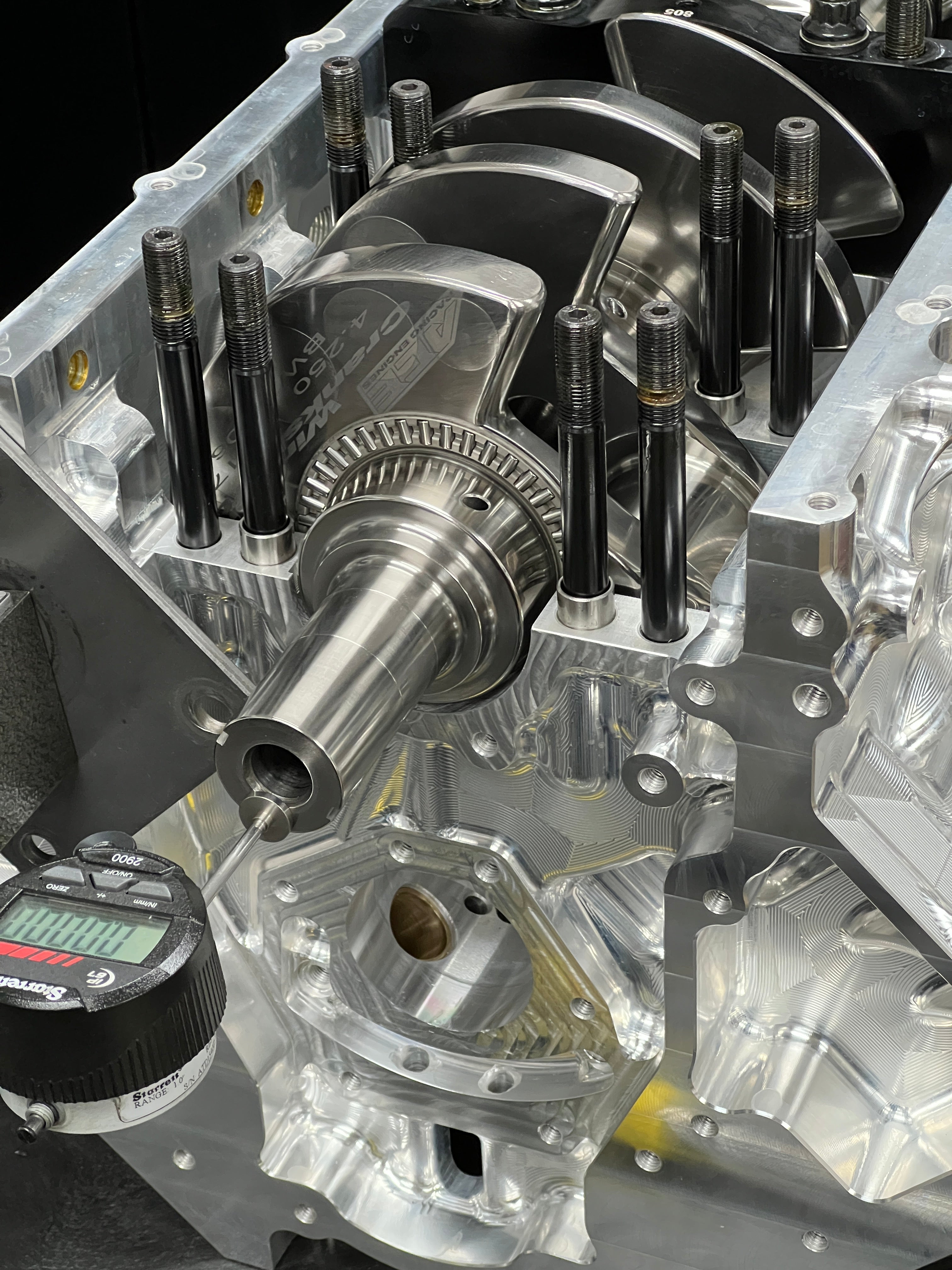

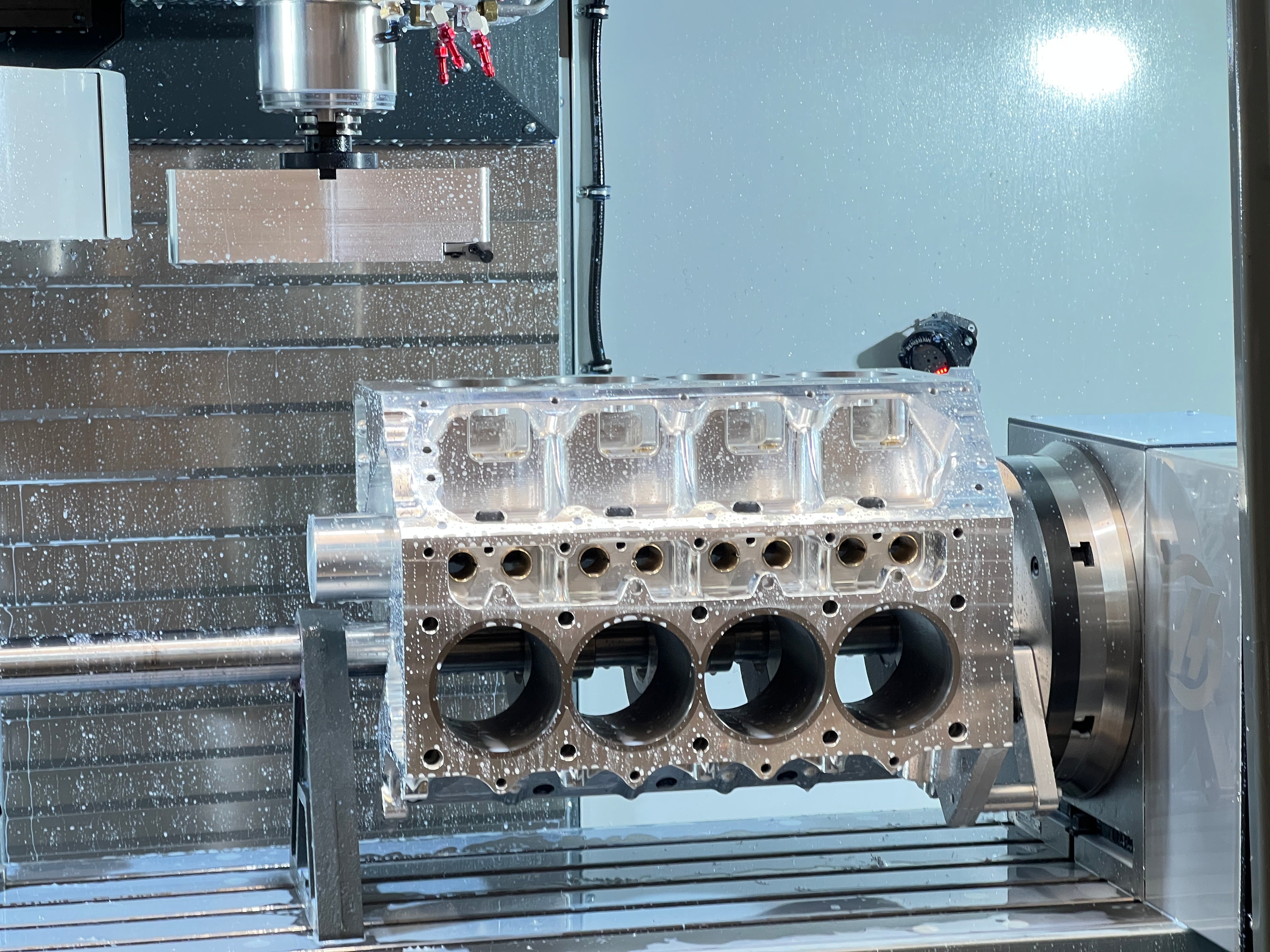

Welcome to the heart of our operation - where precision, technology, and craftsmanship come together to build championship-winning power. Our in-house machine shop is fully equipped with some of the most advanced tools in the industry, including a Sunnen SV30 CNC cylinder hone for perfect bore geometry and unmatched finish control. Each block is CNC machined and finished in our 4 axis CNC block machine. Every surface, clearance, and tolerance is machined with purpose - ensuring consistency and performance you can count on.

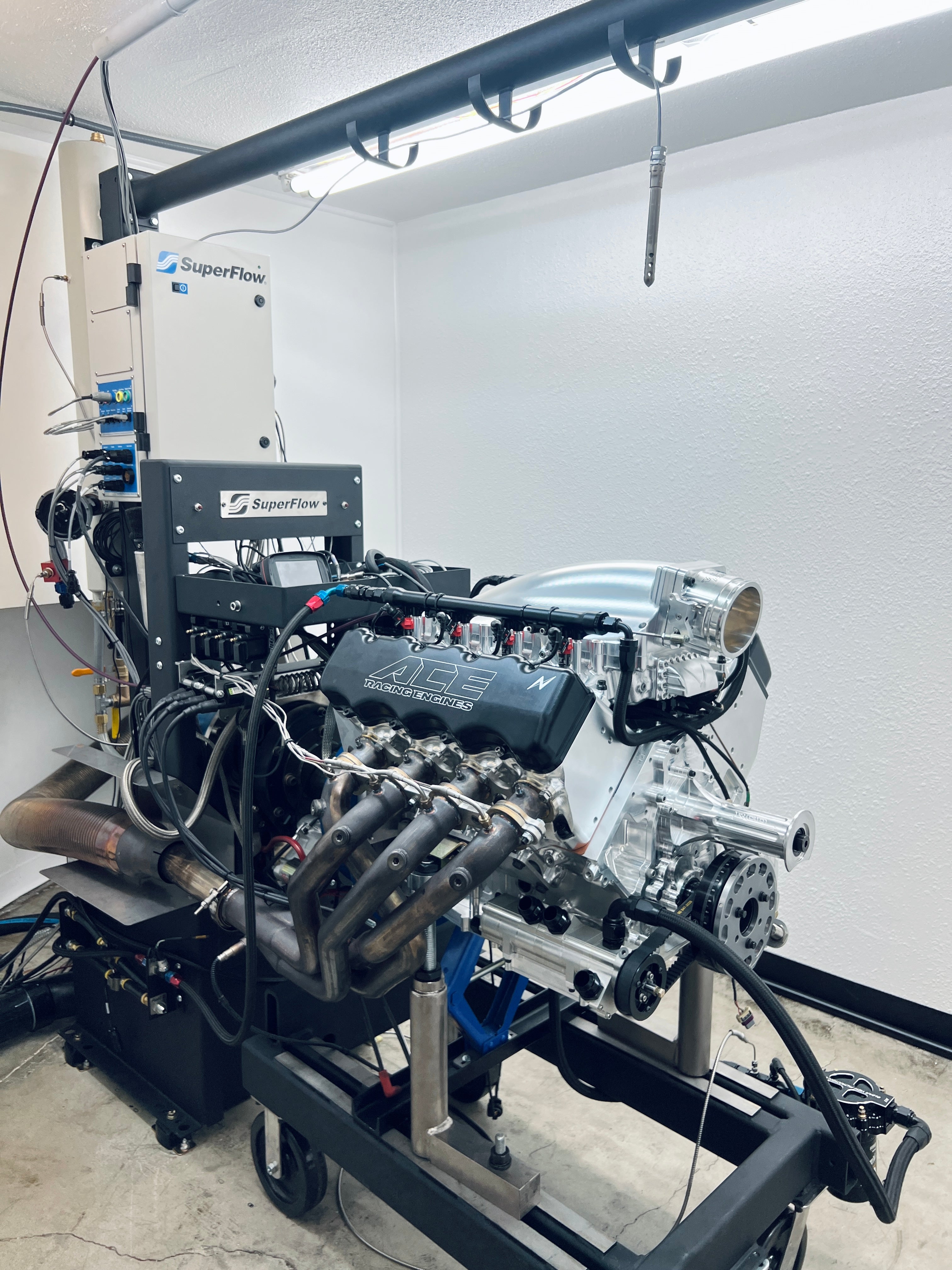

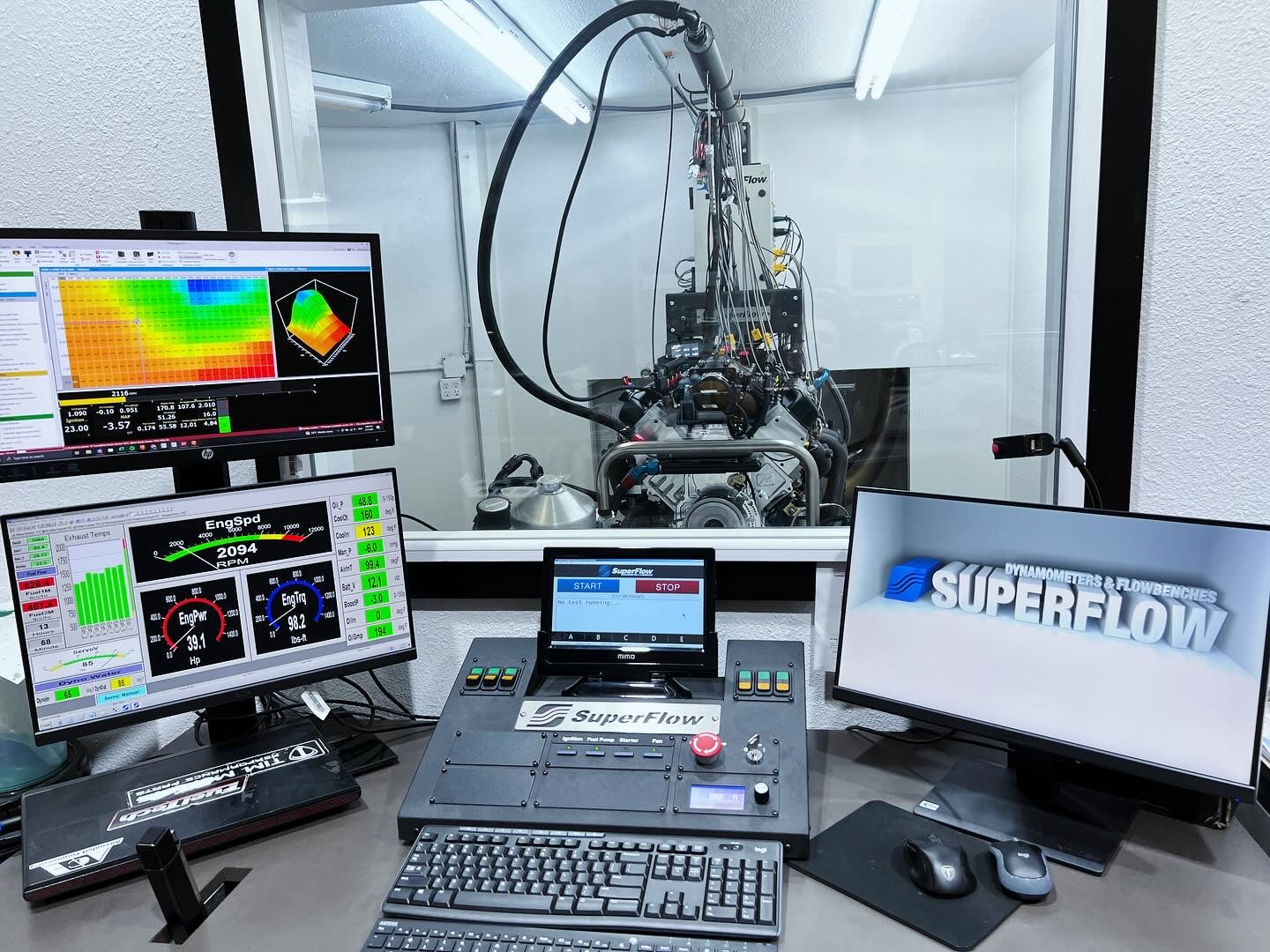

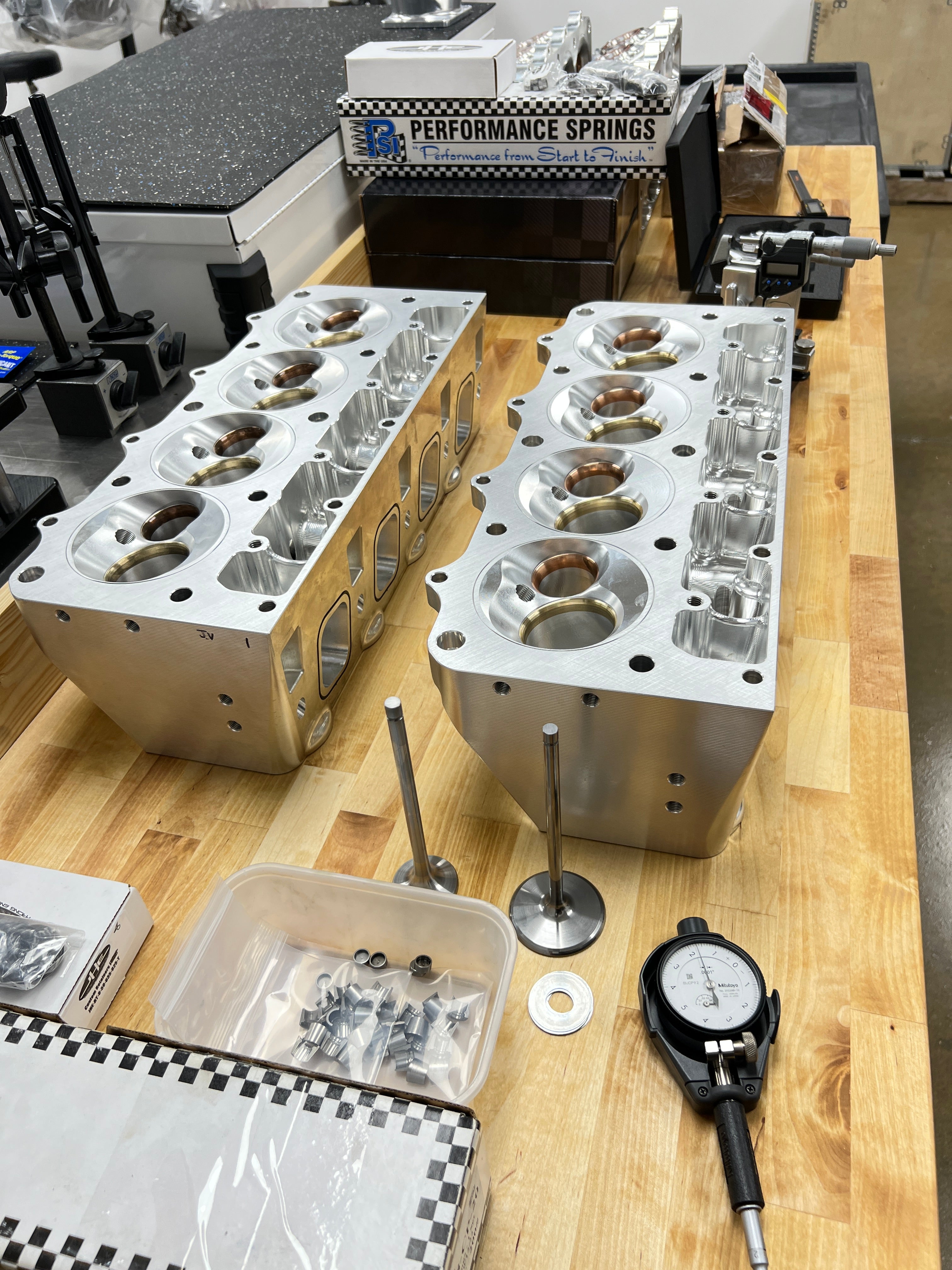

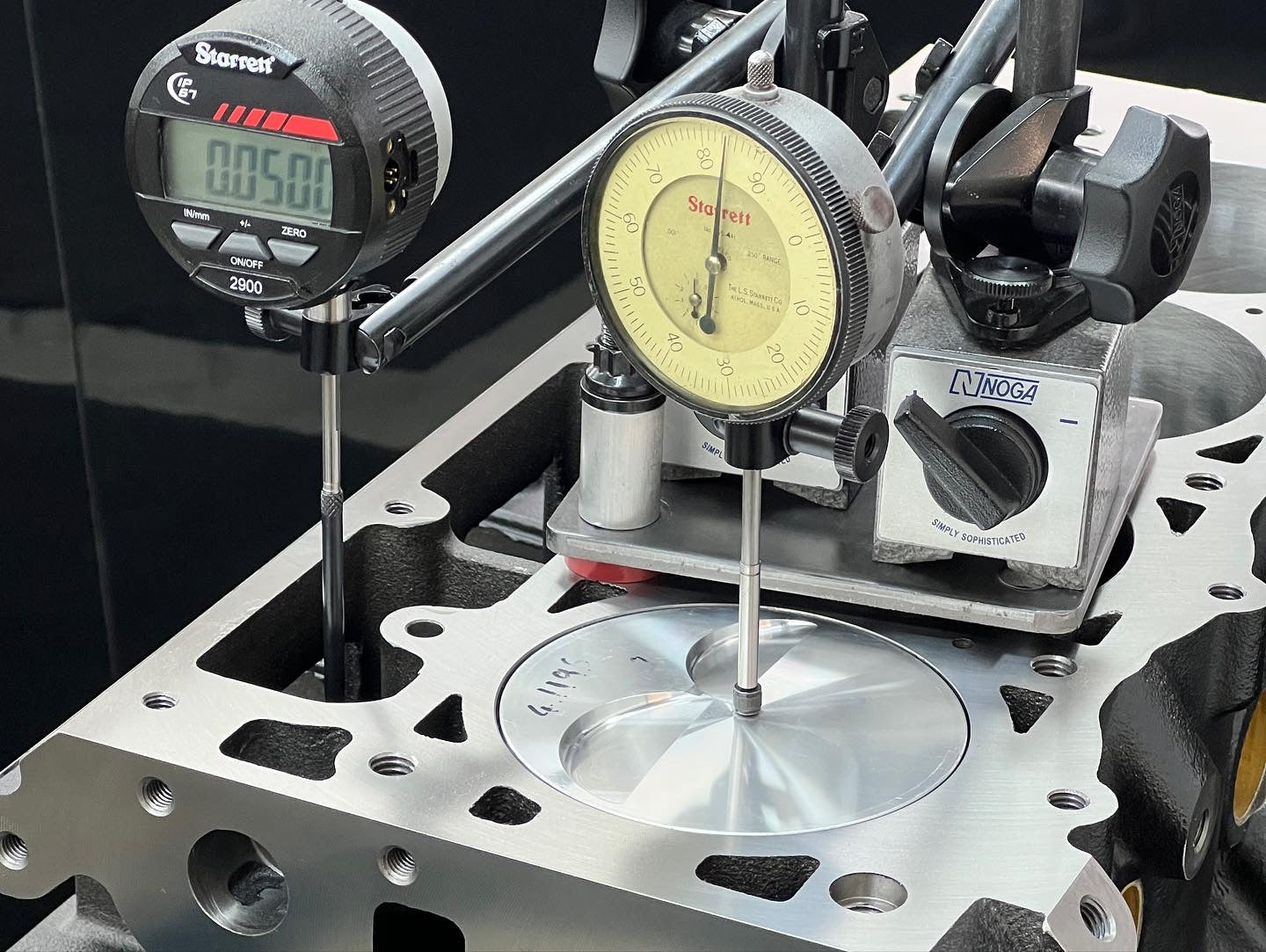

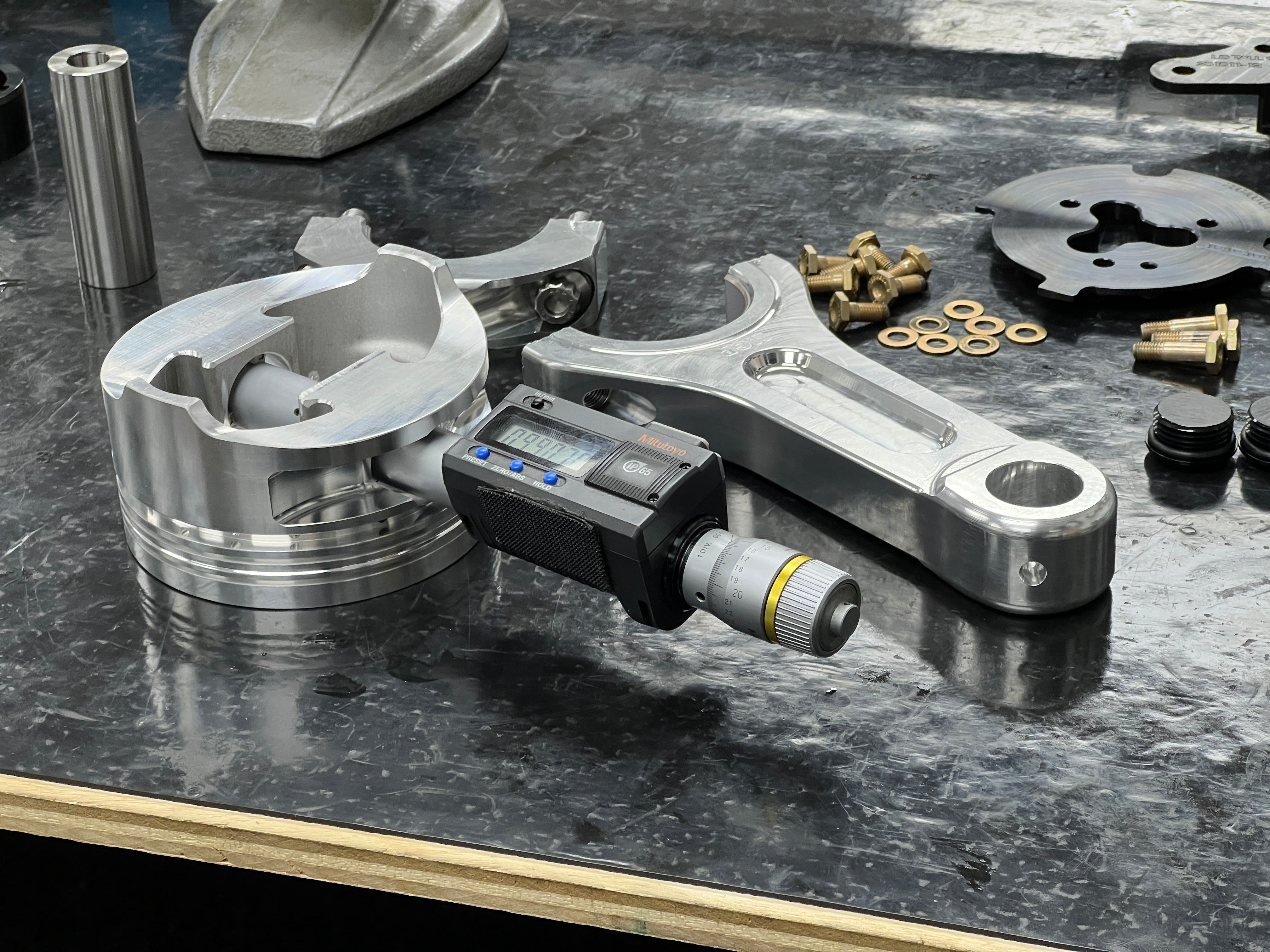

Inside our climate-controlled clean engine room, you’ll find the latest in precision measurement systems and valve spring testing equipment, allowing us to validate every component before it goes into an engine. For development and continuous improvement, our SuperFlow 902 engine dyno is the backbone of our R&D program, testing and refining new combinations to stay ahead of the competition.

Explore the images below for a behind-the-scenes look - or reach out to schedule a personal tour and see firsthand what goes into every engine we build.