Author: Laura

Show Filters

Showing 1–16 of 75 results

-

-

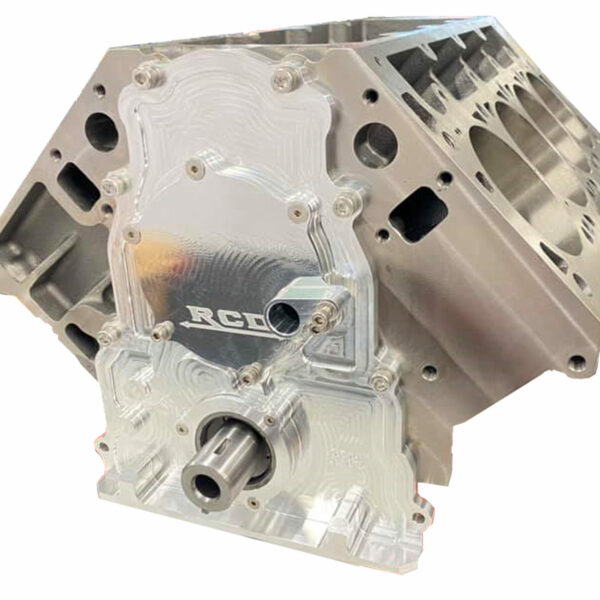

-5%

$4,107.27$3,901.90 Add to cart -

-

-

-

-

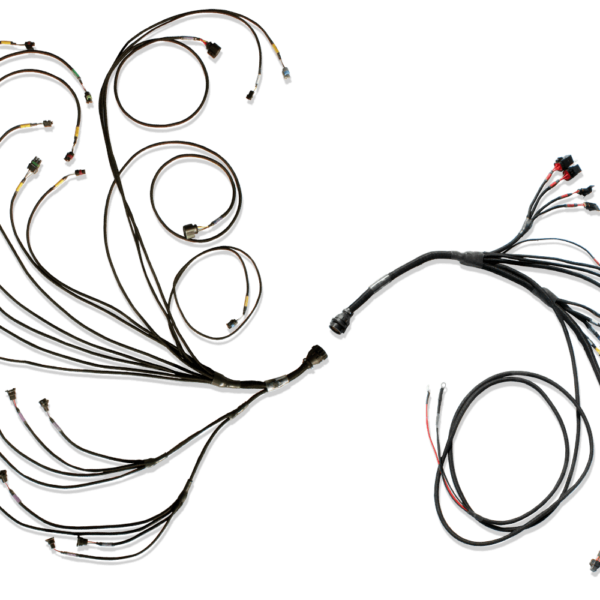

$1,564.99 Add to cart

$1,564.99 Add to cart -

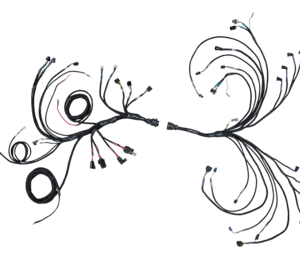

$1,564.99 Add to cart

$1,564.99 Add to cart -

-

Out of stock

-

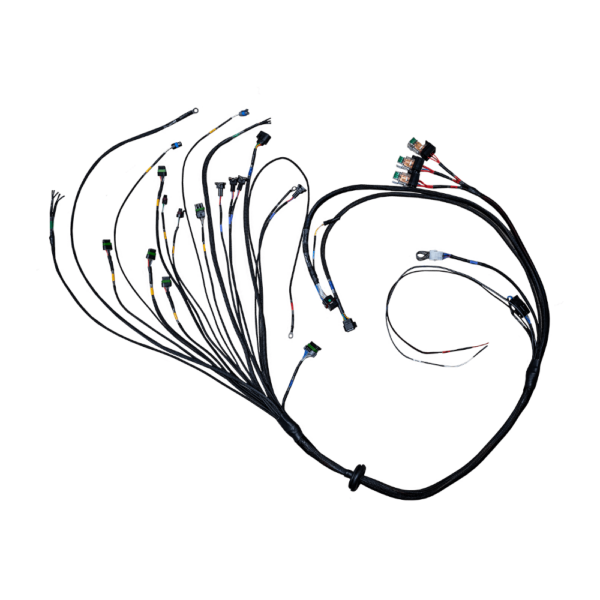

-6%

$1,275.00$1,195.00 Add to cart -

Out of stock

-

-

-10%

-

-

Showing 1–16 of 75 results